Integrating Quality Control Documentation into the Open-Source Hardware Design Workflow

The Challenge

There are now a wide range of open hardware projects available which provide creators with the required instructions for replication, making it possible for people all over the world to produce their own devices. However, these instructions lack provisions for design improvement and record keeping that enable quality auditing.

The Solution

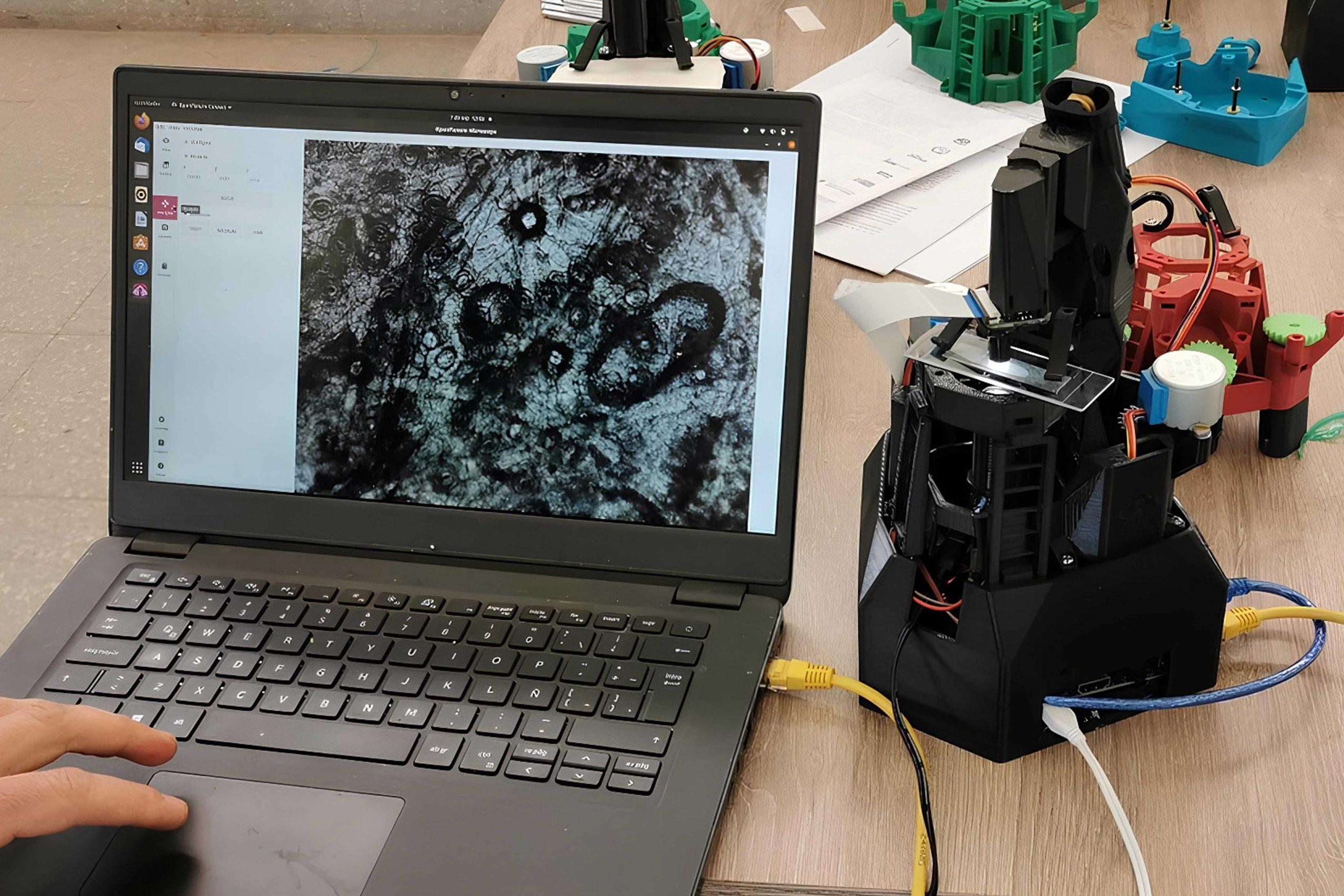

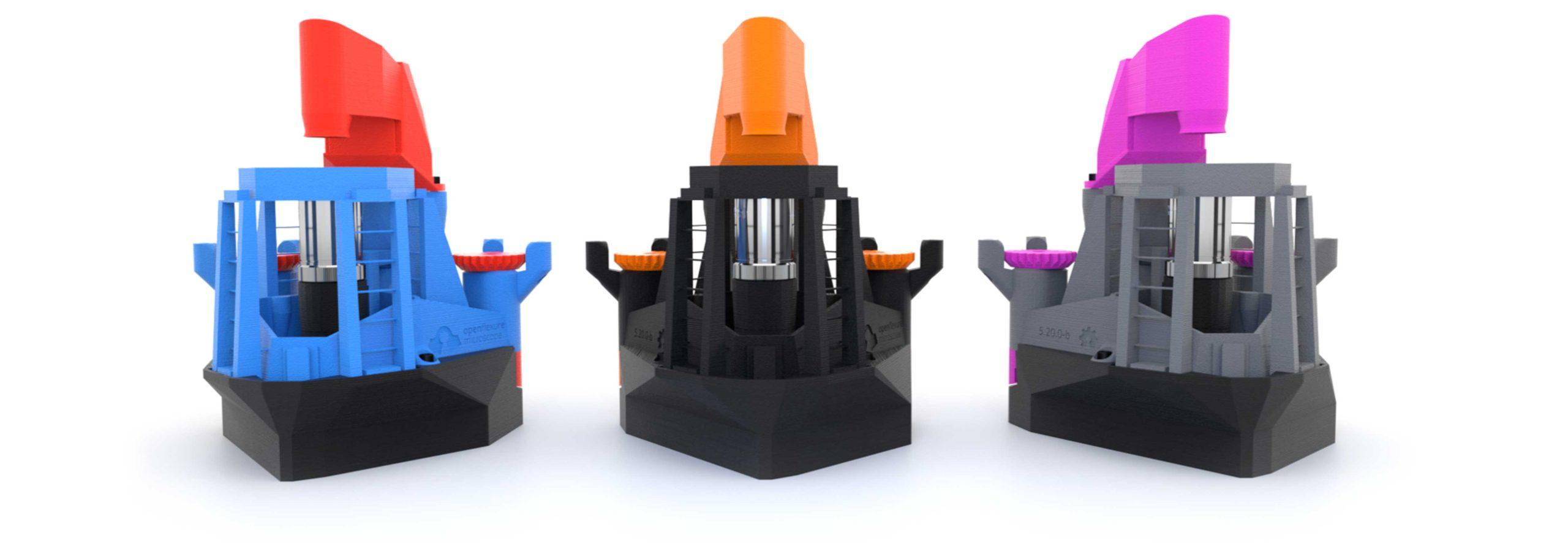

This project is seeking to provide a model solution in which quality checks and data capture are integrated into the assembly instructions for the OpenFlexure Microscope, an open source digital microscope developed by the project team. The microscope has already been replicated and put to use in over 50 countries, with its success owing mainly to its high-quality documentation so that assembly is reliable and components easily sourced locally. By enabling people to provide detailed feedback and facilitating better record keeping, the project aims to overcome challenges presented by a lack of quality checks. Overcoming this barrier will lead to the development of a quality assurance/quality control toolkit, to be integrated into hardware assembly instructions and progressing the OpenFlexure Microscope from small scale production to the sales of kits and assembled microscopes.

The project was successful in responding to the pro² network’s 2024 funding call ‘Infrastructure for Device Production‘, which seeks infrastructure solutions beyond traditional manufacturing that support the production of digital devices.