Robust Digital Devices for Harsh Environments

The Project

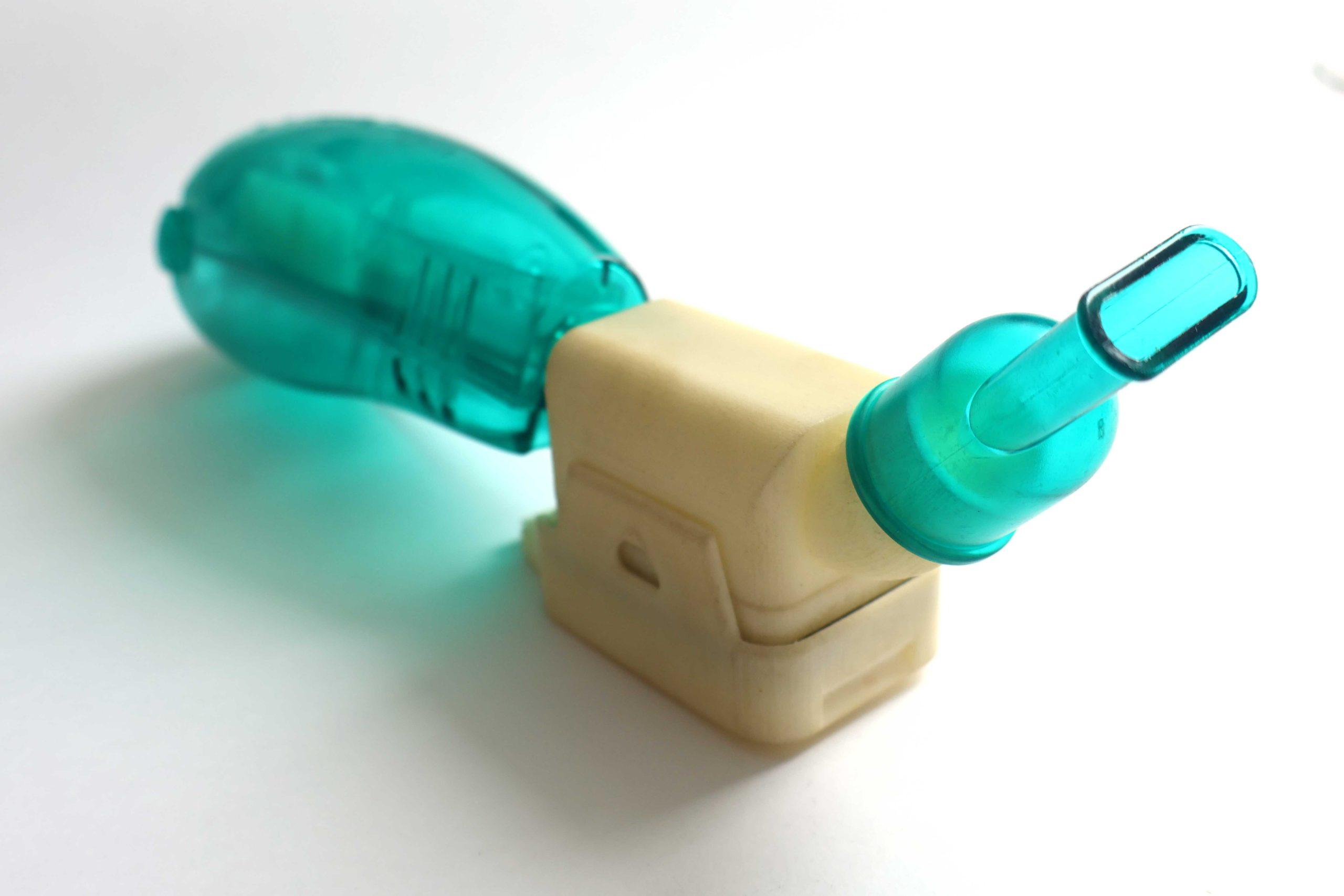

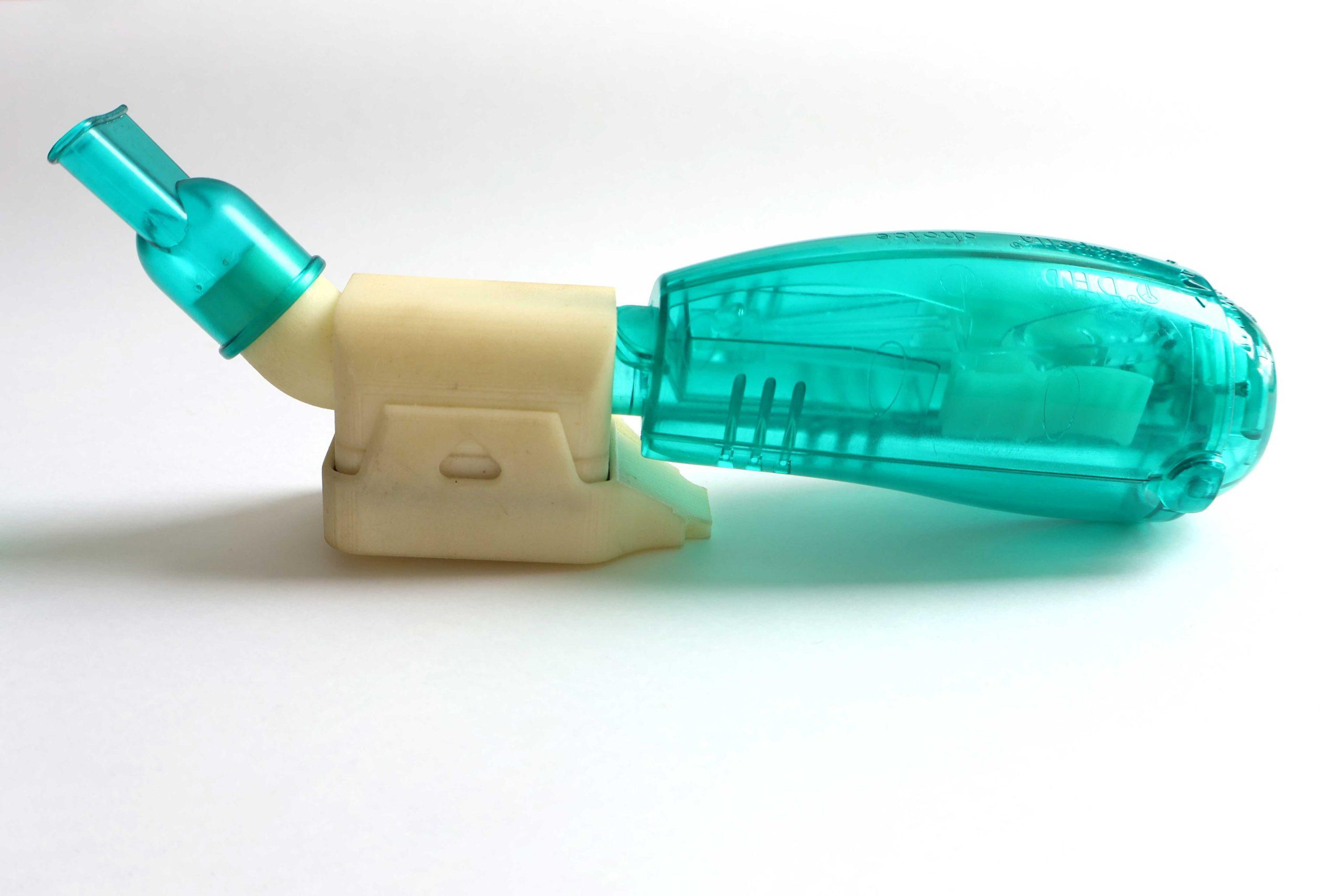

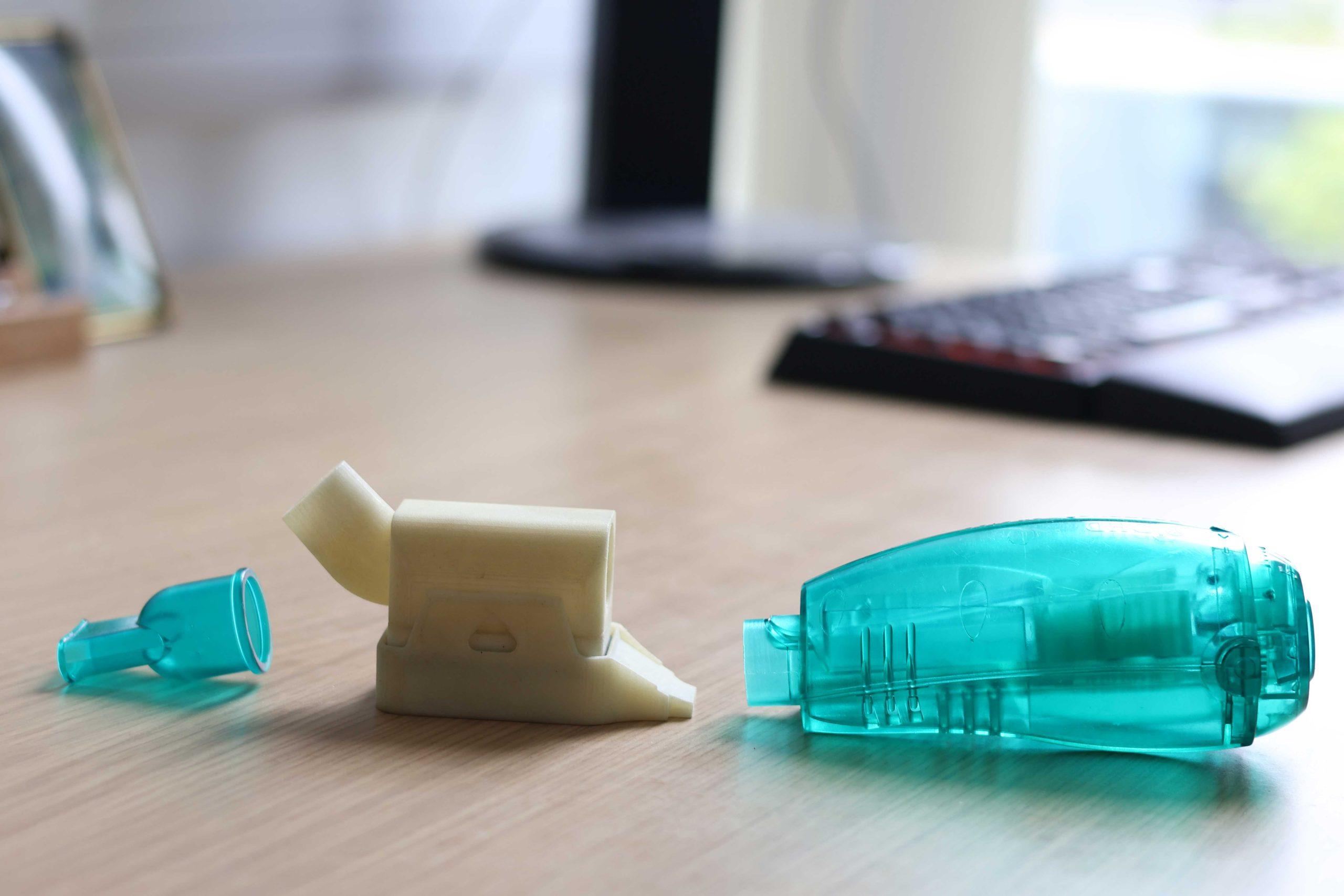

Chest Physiotherapy (CPT) is a common treatment for children with chronic lung conditions like cystic fibrosis or bronchiectasis. Repetitive and frequent CPT is boring for many children, leading to difficulties in adhering to treatment plans. New Zealand-based company Complay Health solves this problem by gamifying the experience using a game controller with sensors for movement and breathing. Unfortunately, this comes with replicability challenges, as the device must be both affordable and robust enough to withstand regular sterilisation in boiling water and use by children who may handle the device roughly.

The project aims to find solutions to these problems and ultimately serve as an exemplar for the scalable replication of digital devices used in harsh environments. It is doing this by creating an affordable, replicable production process for robust casings and electronics that can withstand heat, water, and mechanical forces. The results have the potential to be transferred to a wide range of devices used in healthcare, sports, entertainment, industry and agriculture.

This project was successful in responding to the pro² network’s 2023 funding call ‘Replicability‘ which aims to solve challenges related to the replication of digital devices for testing or production purposes.

How You Can Help

If you know or work with any children who are affected by chronic lung conditions, please get in touch with project lead Christof Lutteroth who is currently seeking research participants. By supporting this project, you can make a difference for the many children impacted by these conditions.