Why pro²?

Typical manufacturing processes work when you want to produce high volumes of a product with commonly used materials, such as mobile phones or television screens. This is because producing devices in high volumes or with common materials is more cost-effective: it absorbs the burden of high non-recurring expenses, is less risky than working with unusual materials, and is likelier to be supported by existing manufacturing processes and infrastructure.

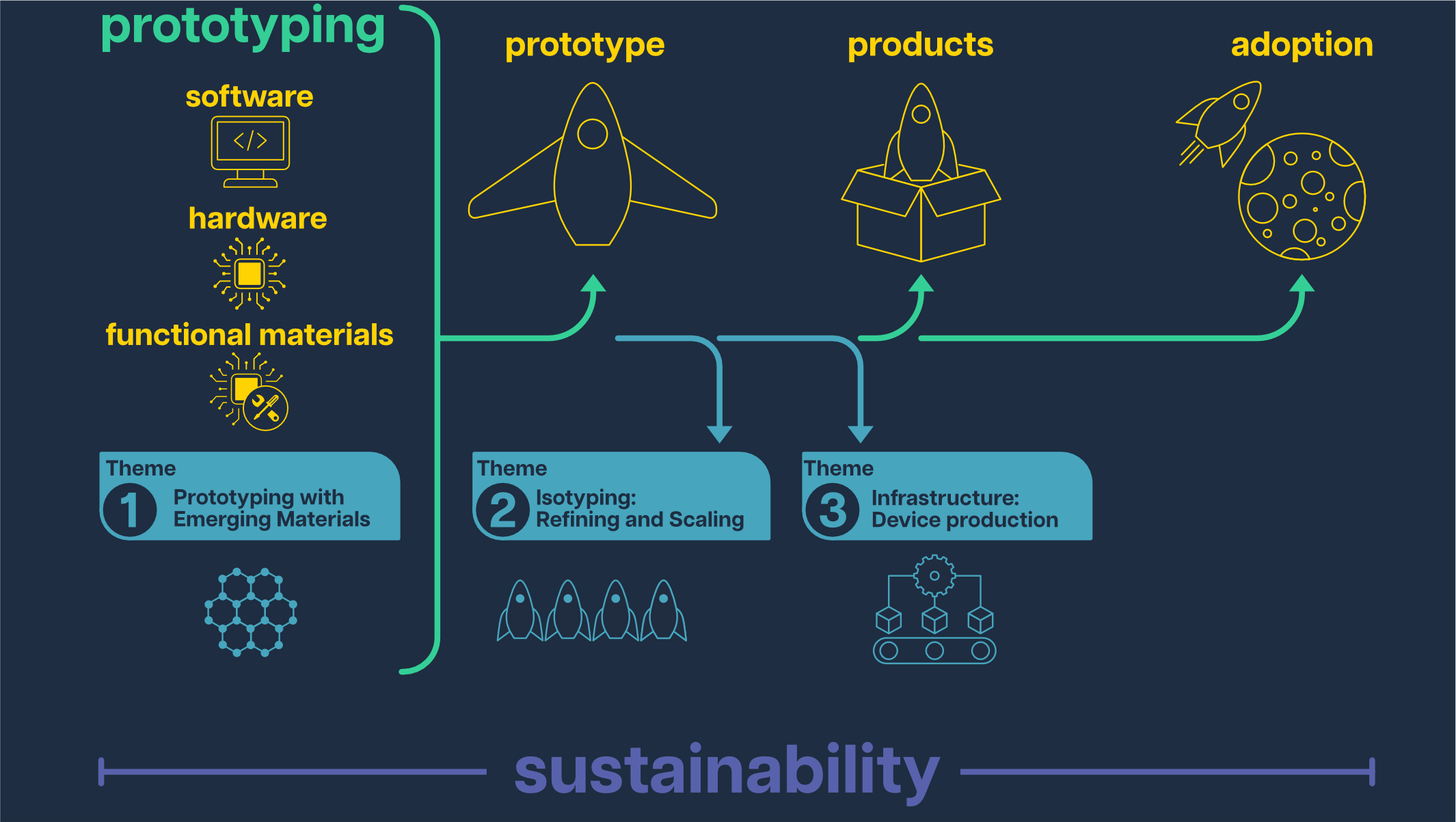

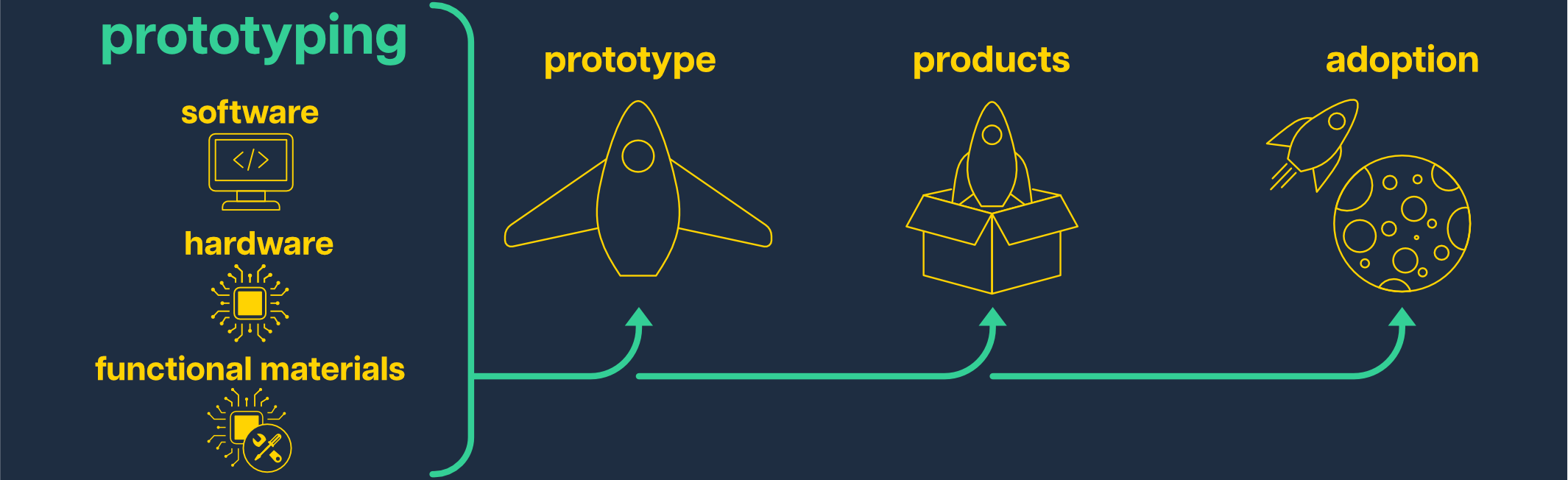

Typical production process for digital devices:

But what if you only need a low number of something, such as a specific medical device for people with a rare condition? Or you want to create a device using unusual materials, such as electronic ink?

Serious challenges begin to emerge when people try to manufacture digital devices in low volumes or using unusual materials. As a result, many devices that would improve people’s lives never make it to market.

To make low-volume production easier, pro² will focus on three themes:

Tackle the challenges

To tackle the challenges shown above, we have grouped them into themes, each led by members of the pro² network+ steering group.

Theme 1: Prototyping with Emerging Materials

Led by Professors Anne Roudaut and Jason Alexander, this theme aims to tackle the challenges associated with making digital devices from unusual materials. Key considerations include:

- What kind of material can be used to make digital devices that hasn’t been utilised yet?

- What kind of form factors are available for unconventional electronics? E.g. spraying

- How do we bring people together in this space to spread knowledge, trade material and expertise and collaborate across different disciplines?

- How do we test unconventional electronics, make them safe for use and embed tutorial knowledge into the tools we use for creation?

Theme 2: Isotyping: Refining and Scaling

Led by Professors Joe Finney and Steve Hodges, this theme seeks to build and evaluate new tools and techniques that support organic scaling through iterative refinement, making it easier to move from a one-off prototype to low volume copies, which pro² call isotypes. Specific objectives include:

- Finding ways to facilitate simple and cheap replication, including easy to use design tools for low cost devices.

- Improving support available for reliability, testability and compliance, including integrated design of devices and device testing.

- Generating better supply chain flexibility to enable substitutability of components and manufacturing services.

- Ensuring that environmental impact is minimised.

Theme 3: Infrastructure for Device Production

Led by Professors Boriana Koleva and Mike Fraser, this theme aims to make it easier for stakeholders to interact and collaborate remotely around the digital device production processes. Specific areas of interest include:

- Infrastructure for testing, including networked/remote evaluation, testing and debugging, and creating tools for prototyping that enhance progress towards isotypes, including design platforms which consider reliability, testability, compliance, inventory management and scalability.

- Infrastructure for audit, including enabling remote sustainability and ethical audits. This could either be for or in collaboration with standards and regulators. These systems might underwrite pay-as-you-go manufacturing approaches which lack supply chain provenance.

- Infrastructure for product iteration, including support for distributed manufacturing that refines IoT infrastructure in a way that bridges the gap between the highly iterative hackspace and the very linear production line.

- Infrastructure for replication, including an increased ability to share open-source hardware designs easily between makers and manufacturers. For example, what can we do with Instructables to make it more like GitHub?